One Japanese company that got its start making grinding wheels for machinery more than 80 years ago believes it holds the key to helping manufacturers create ever slimmer and more powerful semiconductors to power next-generation mobile phones and advanced computers.

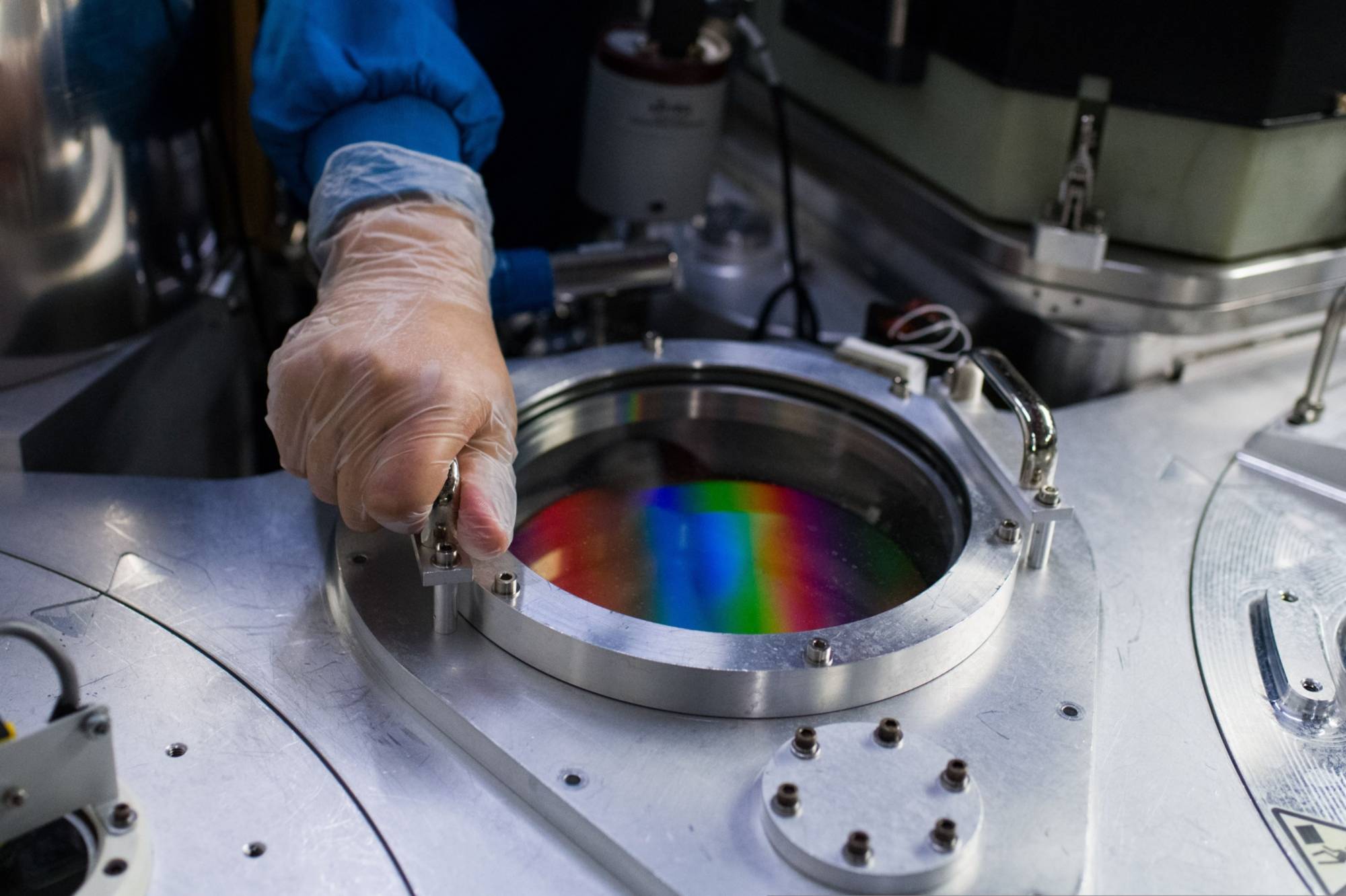

Disco Corp.’s machines can grind a silicon wafer down to a near-transparent thinness and cut the tip of a hair into 35 sections. That know-how will allow chipmakers to stack integrated circuits on top of each other in a process called 3D packaging, promising smaller chip footprints, reduced power consumption and higher bandwidth between various parts.

"Imagine having to cut a croissant cleanly in half,” Disco’s Chief Executive Officer Kazuma Sekiya said in an interview. "That takes a special kind of knife and considerable craftsmanship.”

With your current subscription plan you can comment on stories. However, before writing your first comment, please create a display name in the Profile section of your subscriber account page.