A Tokyo machinery maker will launch a cutting-edge research and development center for robots in Minamisoma, Fukushima Prefecture, in April to support the recovery of the disaster-hit prefecture.

Kikuchi Seisakusho Co., led by President and CEO Isao Kikuchi, a native of the local village of Iitate, plans to hire workers from the area and outsource services to local businesses, hoping to support reconstruction of industry in the Soso area in the prefecture's eastern edge.

"We want to help the recovery (of Fukushima) by doing what we can as a manufacturing company," said the firm's director, Naotaka Otogawa.

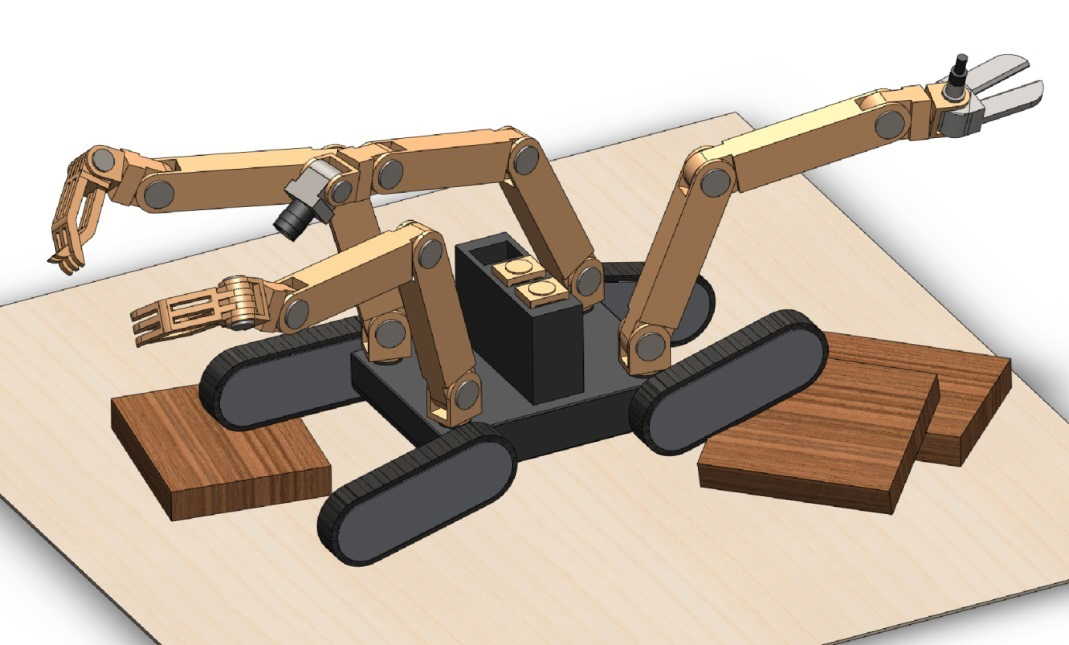

The first product from the facility eyed for commercial production, which will be carried out in Odaka Ward, is a postdisaster debris-clearing robot with four arms, a world first, according to company officials.

The company, which has its key plant in Iitate, will set up the research center for joint development projects with universities and research organizations. It will be located inside the company's new Minamisoma factory to replace an office that fell into disuse after the Great East Japan Earthquake and tsunami of March 2011. Universities that have worked with the manufacturer will have their labs within the facility, which will be equipped with sophisticated instruments to measure the performance of the robots.

The plan is to use Kikuchi Seisakusho's technological know-how to give shape to the universities' advanced technologies in the form of products and bring them onto the market.

The Minamisoma factory, whose area totals some 45,000 sq. meters, roughly the equivalent of Tokyo Dome, will be capable of conducting large-scale tests necessary to bring trial products to the market.

The four-armed robot, under a joint project with Tokyo's Waseda University, will be superior to more common one-armed debris-removal robots that are being developed in Japan as well as overseas, in that it can cut debris into pieces and transport them at a much faster pace, according to company officials.

Another product eyed for commercial production is a remote-controlled helicopter. Developed with Chiba University, the helicopter can stay airborne for extended periods thanks to a cable that connects it with a power source on the ground. Researchers believe it will be useful in monitoring a disaster-hit area as well as in fire-extinguishing operations in forest fires.

The University of Tokyo and the National Institute of Advanced Industrial Science and Technology are two of the members that will jointly develop a motor-loaded machine that helps people walk, particularly the elderly and people with disabilities. The machine is aimed in particular for when people need to evacuate from a disaster area. The machine is also aimed for use at elderly nursing care facilities and shopping centers, said the officials.

The officials said the products will debut starting from spring 2016. The company has already started to manufacture parts at the Iitate factory, supported by prefectural government subsidies.

The company plans to hire 25 workers locally for the launch of the Minamisoma plant and the new research center, and outsource processing and manufacture of parts to Soma-area companies, aiming to make robot production a key industry of the area to help stimulate the local economy.

This section, appearing every third Monday, focuses on topics and issues covered by the Fukushima Minpo, the largest newspaper in Fukushima Prefecture. The original article was published Nov. 8.

With your current subscription plan you can comment on stories. However, before writing your first comment, please create a display name in the Profile section of your subscriber account page.