Installed offshore wind capacity is expected to reach 650 gigawatts globally by 2050.

The Norwegian government has plans for 30 GW of offshore wind power by 2040, 75% of which will be floating.

The floating offshore wind turbine (FOWT) industry is in its infancy with only a few units in operation.

Ingvar Apeland, CEO of Ocean Ventus (major owner: J.J. Ugland Group) aims make Ocean Ventus an attractive alternative for investors in renewables.

“Based on our deep knowledge and decades of experience of designing floating units for the oil and gas industry, our engineers have designed a substructure for FOWTs that is lighter and more efficient. Ocean Ventus’ substructure is approximately 40% lighter than competing solutions, and subsequently 40% less costly.”

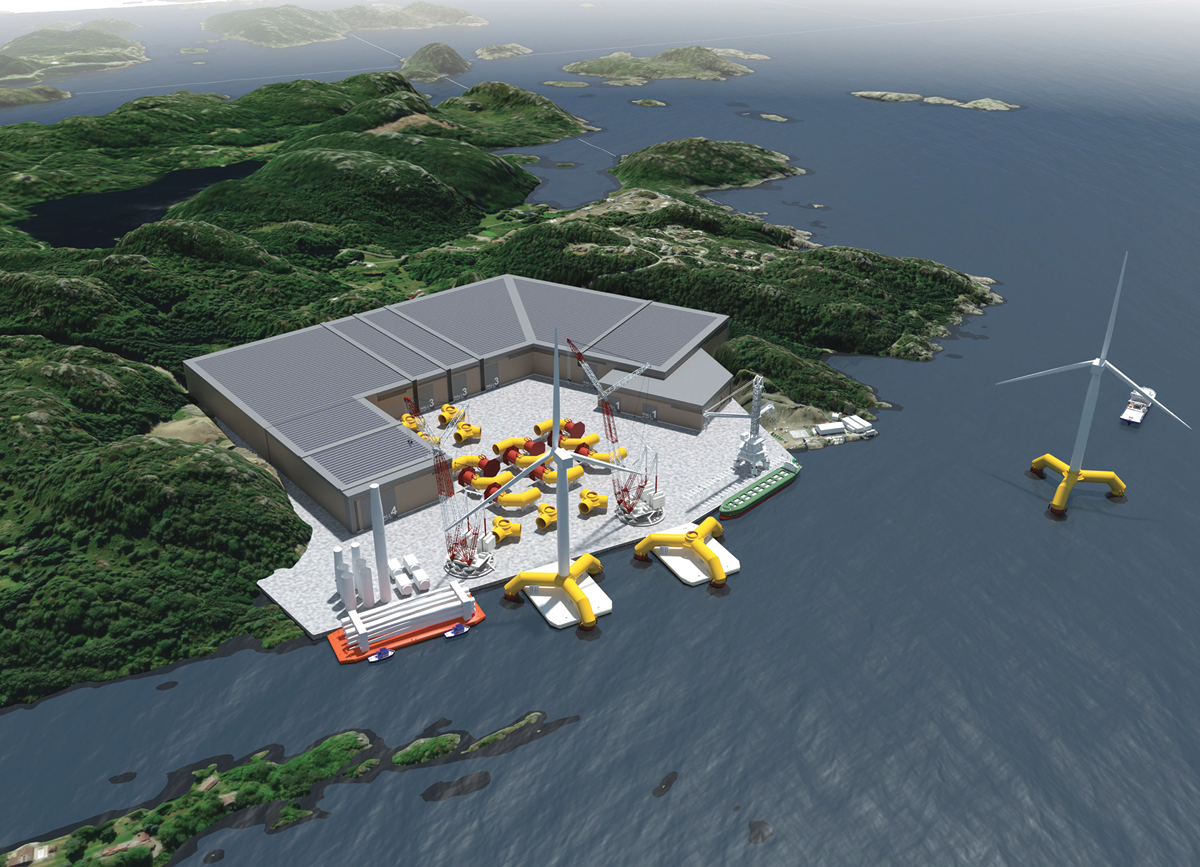

“Today’s supply chain and fabrication methods are not suitable for mass production required to meet governments’ targets, hence new and efficient production facilities need to be built,” Apeland said. “Our Ocean Ventus gigafactory is fully automated and dedicated to producing Ocean Ventus substructures at a rate of one per week. A letter of intent is in place for the first factory in Norway and the concept is applicable globally.”

“Assembly of Ocean Ventus FOWTs takes place on dedicated barges,” Apeland explained.

“Assembly is carried out in an environmentally friendly and sustainable manner. Prefabrication and assembly at the same location minimizes transportation costs and emissions.”

Servicing an offshore wind turbine can be costly for wind farm operators because the turbines typically have to be towed back to shore for heavy maintenance. Not so with Ocean Ventus.

“Ocean Ventus’ specially designed service vessel can handle the heaviest maintenance and repair jobs in the field without having to disconnect the FOWT from its moorings and power cable, thus dramatically reducing operating expenses,” Apeland said.

The Ocean Ventus design, which significantly lowers the levelized cost of electricity, is now being considered for several wind farm development projects.