In April, the American Lumber Standard Committee’s Board of Review approved the design values of two-by-four dimension lumber for sugi (Cryptomeria japonica, or Japanese cedar). This follows approval granted in April 2024 for hinoki (Chamaecyparis obtusa, or Japanese cypress).

This latest approval allows Japanese cedar to be used for building in the United States, the world’s largest consumer of industrial roundwood and sawn wood.

Until now, exports of domestic timber have been on the rise, but roughly 50% of it had been exported as logs to countries such as China. Given that two-by-four construction is the standard method for homebuilding in the U.S., this new approval is expected to lead to an expansion of exports.

Several companies, including Kyowa Mokuzai, a lumber company with 70 years of history, and The Japan Wood Products Export Association worked hard to obtain this. Shigeki Hata and Koichi Tokugawa of the association and Kyowa Mokuzai President Hirooki Sagawa and Senior Managing Director Wakako Sagawa spoke with The Japan Times about the appeal of Japanese cedar and its sales potential.

Inside the testing process

Kyowa Mokuzai is one of Japan’s largest lumber producers. It operates three factories on its premises, which spans an area that would cover nearly 65 U.S. football fields.

The company provided wood samples for the test, which was held at a U.S. university and witnessed by a team of representatives from Japan. “We went to Oregon State University with the association officials to witness the testing,” Wakako Sagawa said.

Hirooki Sagawa said he is confident in the quality of Japanese cedar. “It’s relatively soft, easy to work with, yet it is also durable and strong,” he said. “It has many other excellent properties, such as resistance to rain and UV light. It does not crack easily when used outdoors.”

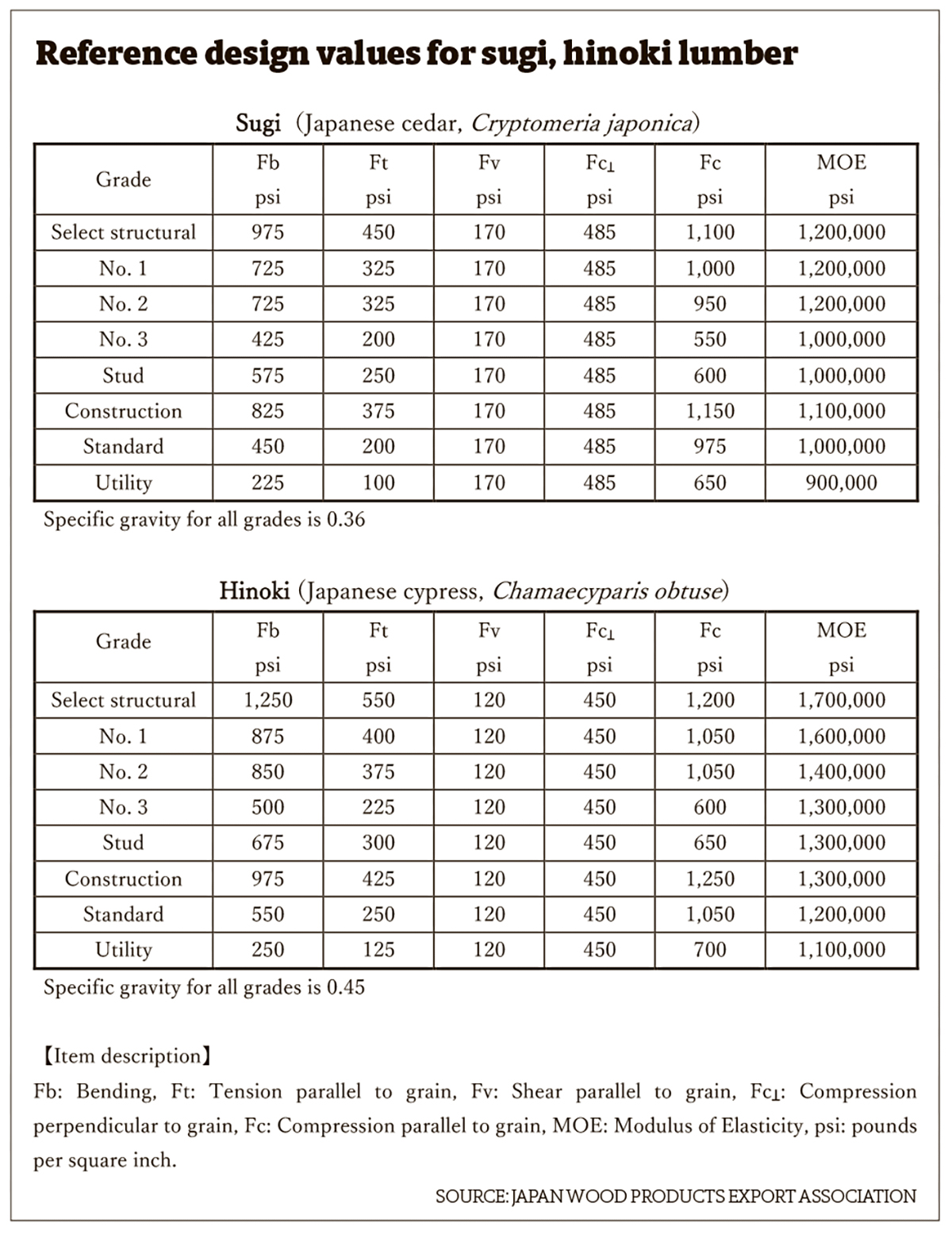

Hata explained that the strength of No. 2 grade Hinoki, which is the most common, is comparable to spruce-pine-fir (SPF), while sugi is comparable to German-grown Norway spruce.

Whitewood, such as Norway spruce, is imported to the U.S. from Europe. In North America, SPF is widely used for two-by-four construction, and we expect sugi and hinoki to be used in similar applications,” Hata said.

Sugi and hinoki are widely used as building material in Japan. However, gaining broader acceptance in other countries requires building trust. The U.S. recognition of its design strength is a significant step because it provides numerical evidence that Japanese cedar is suitable for architectural use.

For house building in Japan, cedar is sorted by grade for different applications. Lumber of higher grades is used for sections that need to bear significant loads, such as horizontal beams, while lower grades are used for studs and other sections that will bear lesser loads.

“Some of the lumber is sorted by intended use even at the felling stage. For instance, we identify trees that are best suited for columns or those that can be used for beams and girders while they are still standing,” Hirooki Sagawa explained. Furthermore, during processing at the sawmill, the quality is carefully checked again for more precise sorting by use and subdivided even further for specialized applications.

In the U.S., Japanese cedar is becoming popular for fence-building, rivaling western red cedar in ease of use for decks and fences in the U.S.

Kyowa Mokuzai has been exporting fencing material made from sugi since 2018. This venture began unexpectedly when Hirooki Sagawa heard that China is importing a lot of logs from Japan.

“Initially, we didn’t know what the logs would be used for,” he said. “But eventually, we discovered that they were being milled in China and then exported to the U.S. as fencing material.”

As a manufacturer, Kyowa Mokuzai is committed to processing Japanese resources within Japan and takes pride in delivering products of the highest quality to its customers. The company quickly set up a dedicated production line to manufacture fencing materials for the U.S. market. To ensure competitive pricing, the company installed state-of-the-art machinery, which helped reduce processing costs. This move has provided the U.S. market with access to high-quality, affordable products crafted with Kyowa Mokuzai’s renowned processing technology. By incorporating log-cutting based on feet and inches — alongside traditional domestic standards — forestry operations have successfully increased yield while aligning with export specifications.

Kyowa Mokuzai also exports lumber for decks, a common feature of American homes. Hirooki Sagawa believes that, even when selling exterior materials like these, “having the approval is a plus because it proves that the product is good enough for building houses, which gives consumers a sense of assurance.”

Tokugawa said that U.S. recognition of sugi will be a strong impetus for exports elsewhere.

“It is expected to fuel exports of lumber to countries such as China and South Korea, where two-by-four housing is becoming popular, “ he said.

While many countries have their own lumber standards, Hirooki Sagawa pointed out that some countries accept American standards. “We have high hopes that U.S. approval will boost the sales of Japanese lumber for construction worldwide.”

Spreading global appeal

To promote sugi worldwide, a stable supply is critical to success, but all four experts interviewed expressed no concerns on that front.

Japan’s history with wooden architecture dates back to ancient times. To support domestic demand, Japan has a long history of sustainably managing its forests. The “Manyoshu,” an anthology of poems compiled around the eighth century, contains descriptions of cedar planting, and records indicate that large-scale cedar afforestation began around 1500. During the Edo Period (1603 to 1867), forests were already being cultivated to leverage their multifaceted functions, such as preventing soil erosion, protecting water sources, creating windbreaks and preventing coastal sand drift, all while meeting increasing demand for timber in large cities. Numerous historic wooden structures still stand across the country, showcasing traditional techniques and masterful designs using wood.

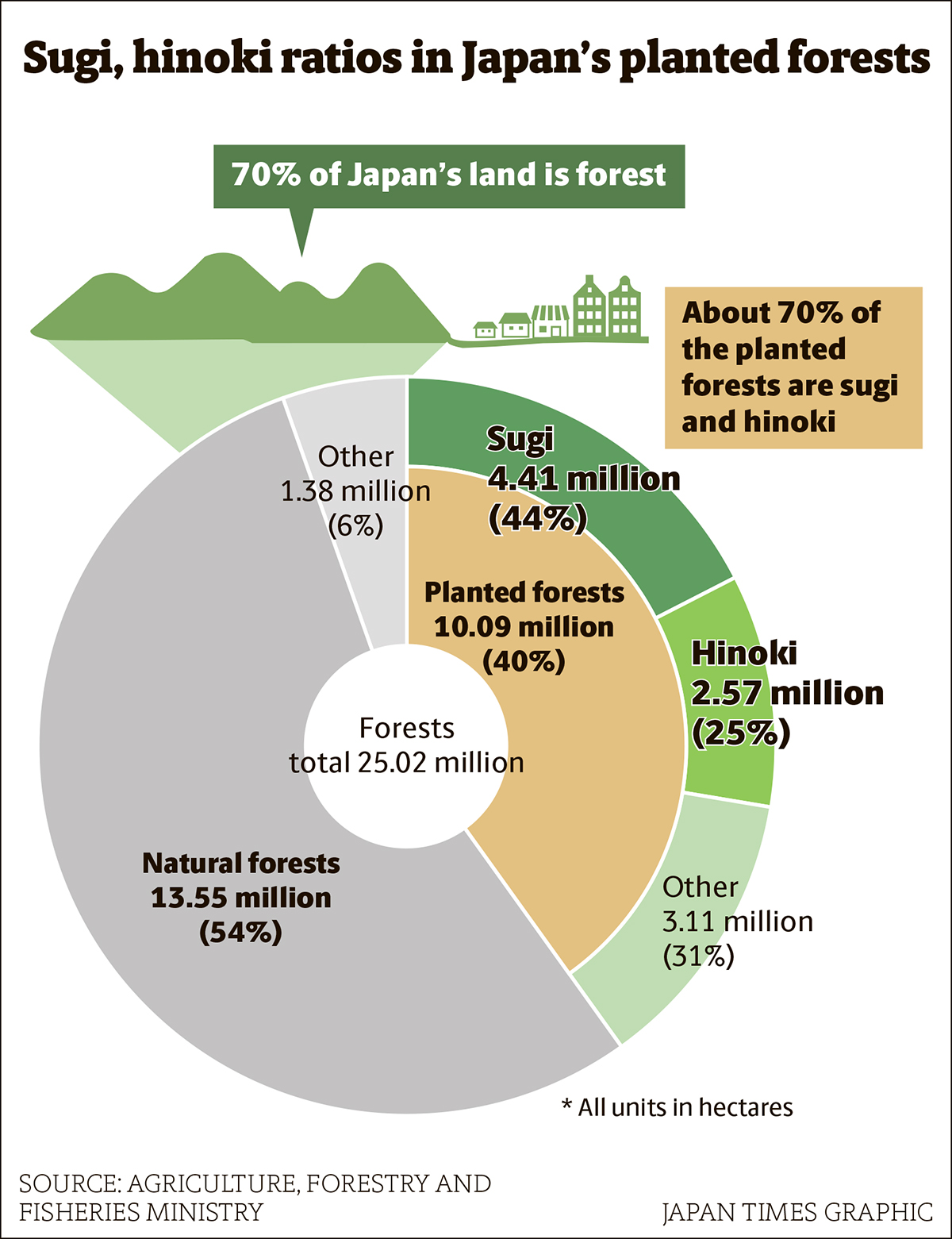

Today, forests cover some 25 million hectares, or about 70% of Japan’s land area. About 10 million ha of this are planted forests, with sugi accounting for 4.4 million ha and hinoki 2.6 million ha.

These planted forests were established after harvesting to meet the growing demand for lumber in the 1950s and 1960s and the planting of trees on sites previously used to produce fuelwood that had been harvested for pulpwood (chips).

Hata stated that the current timber volume of these planted forests is about 3.5 billion cubic meters, and that Japan’s forest resources — driven primarily by planted forests — are increasing by roughly 60 million cubic m annually. In 2023, the nationwide production volume was about 34 million cubic m, of which 16 million cubic m were used for construction materials. Production volumes are expected to continue increasing.

“Currently, approximately 60% of Japan’s planted forests have reached their prime harvesting age of 50 years or more. In a growth cycle of planted forests, we are now entering an era where these forests need to be utilized to maintain the cycle,” he said.

This means that the use of timber needs to be expanded. According to the Forestry Agency’s White Paper on Forests and Forestry, against the backdrop of an anticipated decline in the housing market and growing interest in wood as a sustainable resource in recent years, wooden construction of nonresidential and mid-to-high-rise buildings has been increasing.

This trend is partly driven by the revision of building standards and advancements in the technological development of lumber, cross-laminated timber and fire-resistant wood.

The iconic Grand Ring at the Osaka Expo, with a circumference of 2,025 meters to symbolically match the year of the event, incorporates traditional nuki techniques alongside modern construction methods. Nuki is a centuries-old method of interlocking wooden beams without nails or metal fasteners, long used in the construction of temples and shrines.

“However, domestic demand may still not be enough to maintain the pace of logging needed for optimal forest management,” Wakako Sagawa said.

“It is important to harvest trees at the appropriate time, before they reach old age and die standing,” she said. As trees enter senescence, they deteriorate, leading to standing death and eventual collapse.

There are also concerns that when artificially planted forests established at the same time simultaneously reach old age, the risk of landslides and wildfires may increase.

“Trees absorb carbon dioxide during growth. They release oxygen and store carbon as they grow larger. However, if these trees are left to rot or burn in a fire, all that carbon dioxide absorption during their growth process is released in the air,” Hirooki Sagawa explained. Trees planted in forests for timber only contribute to the environment when they are used in a timely manner.

Furthermore, well-managed planted forests, where proper thinning and logging is carried out, have good air circulation and sunlight. This helps maintain a healthy ecosystem and soil, allowing trees to grow healthily too.

Reforestation magic

The regeneration of forests after logging is also essential for the sustainable supply of timber. Kyowa Mokuzai engages in reforestation by providing professional advice and planting trees based on the requests of forest owners.

“We are committed to passing on healthy forests to future generations through careful consideration, such as identifying land suitable for reforestation, avoiding excessive planting and creating environments that ensure healthy growth of trees and safety for people who take care of them,” Hirooki Sagawa said.

Hata explained that such forest management practices are appropriately implemented in accordance with legal frameworks.

“These legal systems enable the formulation and execution of forest plans that cover both overarching management policies and specific operational methods for individual forests,” he said.

To ensure good forest management over the long term, multifaceted efforts are being made to improve efficiency and secure labor conducive to the often-demanding working conditions in the forestry sector. The use of drones is being promoted to transport seedlings and spread fertilizer. The adoption of high-performance forestry machinery and low-density planting methods have also been promoted.

Development of “elite trees,” which are selected varieties with good wood quality and faster initial growth nurtured via crossbreeding and a stringent selection process, is also progressing. “Thanks to their rapid growth, they require less care and the felling cycles are shortened,” Hata said.

“Declining populations and stagnant local economies have been common issues in rural areas. However, resources such as timber are found mainly in these regions. To utilize them effectively, we are committed to developing business strategies that will revitalize the industry by fostering independent local companies that can grow continuously by earning foreign money through timber exports,” Wakako Sagawa said.

Through these efforts, Japanese timber offers a stable and continuous supply of wood produced under sustainable forest management. This is a significant advantage in an era where there is an accelerating trend toward placing importance on sustainability in the supply chain as well as in decisions in purchasing and consumption. Some countries still cut down trees from old-growth forests for timber even though the pristine ecosystems of such forests can never truly recover once disturbed by human intervention.

Sustainability initiatives

Kyowa Mokuzai is also engaged in various other sustainability initiatives. For example, there are leftovers that often go to waste when logs are processed into straight lumber for construction. The company extracts essential oils from these parts that would otherwise be discarded.

Low-quality logs are used to produce chips for biomass power generation. Wood scraps, bark and planer shavings generated during the manufacturing of building materials are used as fuel for boilers that supply heat to a wood dryer. Any excess heat from the boilers that is not used in the wood dryer is converted into electricity that is utilized to power production facilities. “We aim to engage in biomass power generation itself in the future,” Hirooki Sagawa said.

Timber produced in sustainable ways without damaging old-growth forests is expected to become increasingly valued worldwide. Japanese timber has significant potential in this trend, but it needs to be introduced more broadly to the world. To this end, the association has been participating in international exhibitions including the National Association of Home Builders International Builders’ Show, which was held in Las Vegas in February. The 2025 show gathered more than 81,000 visitors from over 100 countries.

“We are excited to exhibit the appeal of both sugi and hinoki again at next year’s IBS to be held in Orlando, Florida, in collaboration with Japanese timber companies,” Tokugawa said.

Tokugawa revealed that hinoki has a strength close to the Douglas fir, which is known for its exceptional strength and used extensively as a building material in the U.S. While slightly more expensive than sugi, its refreshing scent, white and smooth surface, and beautiful grain are significant attractions. “We believe it is important to showcase these characteristics alongside Japanese culture and its tradition of wood architecture,” he said.

The association also plans to promote sugi fencing materials at Fencetech 2026, which will be held in Indianapolis in February. It will further intensify its efforts to promote Japanese timber in other countries.

“Japan’s domestic population is declining, but I see a bright future for Japan in supplying timber to the U.S. market as well as various countries with growing populations,” Wakako Sagawa said.

This article is sponsored by the Japan Wood Products Export Association. For more information, please visit https://www.j-wood.org/en/