Yamato Scale Co. Ltd., the global leader in weighing technology, has over 100 years of history, starting as Kawanishi Machine Works in 1920. Recognizing the potential of weighing technology, founder Seibei Kawanishi established a Weighing Equipment Department within the company, which laid the foundation for what would later become Yamato Scale in 1945.

Yamato Scale makes a wide range of weighing machinery, but its Dataweigh combination scale has revolutionized the food packaging industry with its precision and speed.

In a recent interview with The Japan Times, Executive Director Ryo Shimizu spoke about the company’s history, and Amanda King, director of marketing and business strategy for Yamato Corp., the company’s U.S. unit, spoke about its global success and contribution to the food packaging industry.

Part of the economic miracle

“In postwar Japan, our company played an important role in rebuilding the country and its economy to develop Japan into an industrial power,” Shimizu said.

The strain gauge load cell, the first electronic weight detection sensor to be put into practical use in Japan, and the optical sorting checkweigher, which achieved automation and high-speed weighing and sorting, were both manufactured by Yamato Scale in the 1950s and contributed greatly to labor-saving efforts in various factories.

“In 1979, we developed Dataweigh high-speed multihead scales with load cells, which have proven to be extremely effective in fixed weighing,” Shimizu said, referring to a technique often used to achieve accuracy and consistency in packaged foods. Yamato Scale was the first company to exhibit multihead combination scales at an international trade fair. “With this, our company embarked on its first stage of global expansion,” he said.

The theory behind Dataweigh

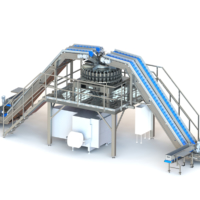

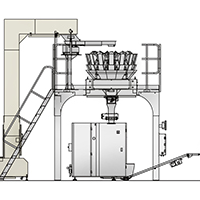

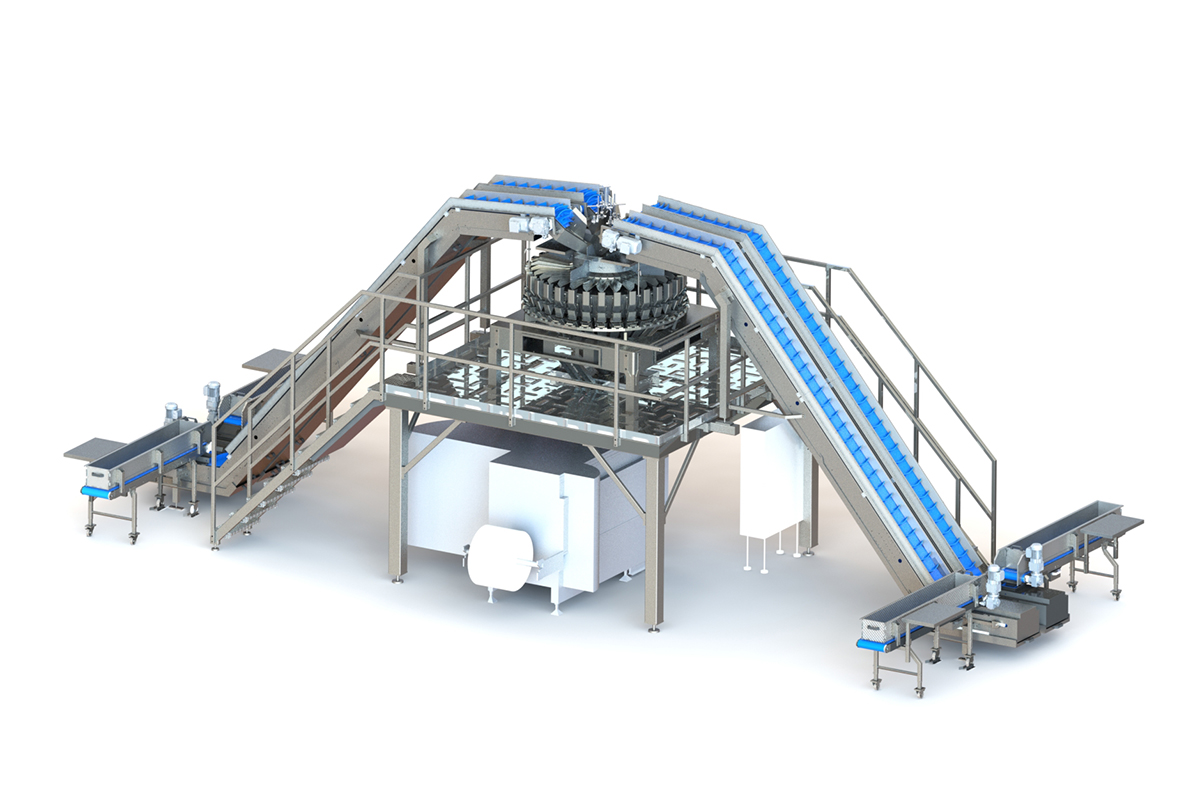

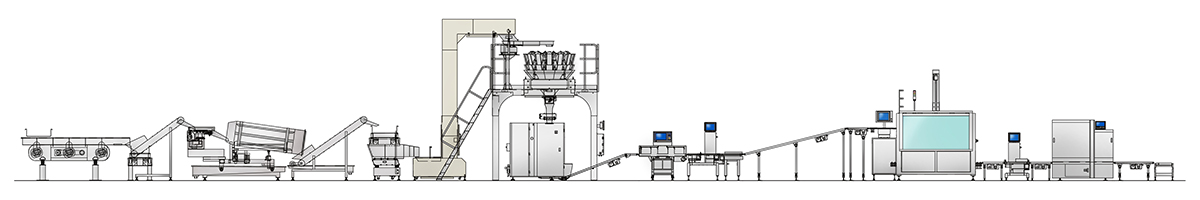

The Dataweigh series is typically installed in production lines used to pack small, granular or powdered items such as snacks, cereals, baked goods, frozen foods, nuts, sugar or coffee to a targeted weight. This involves dividing the item into small portions so the machinery can mix and match them to get as close to the target weight as possible.

This approach, known as combination theory, enables accurate, high-speed weighing.

“We often use the example of apples to explain the benefits of the theory,” Shimizu said. “Let’s say you want to pack a kilogram of apples. One way of weighing is to keep adding apples to the scale until the weight is close to a kilogram. But this method has the potential to create a lot of underweight and overweight” because the solution is reduced to merely adding another apple. However, if a large number of apples can be divided and combined in a way that, when added together, comes closest to a kilogram, the underweight and overweight can be minimized. Multihead weighers do this automatically and quickly.

When using a Dataweigh, raw product lands on its conical top, which vibrates to distribute the product down into radially arranged linear feed pans. The product moves down the pans into feed buckets which, upon receiving a signal, discharge it into weigh buckets. The scale’s software is designed to identify the combination of buckets that will result in a total weight closest to the target, and the contents of the selected buckets are discharged into a package while the contents of the nonselected buckets are used for the next weight calculation.

Since each bucket is constantly in one of two statuses — selected or nonselected — the total number of combinations is determined exponentially based on the number of buckets on the scale. The most common number of buckets on a Dataweigh is 14, which means there are 16,383 possible combinations. “The number of buckets can be adjusted, but more buckets means higher accuracy,” Shimizu said.

Yamato Scale offers several models that are recommended according to various factors, such as what the customer wants to weigh, what the customer’s priorities are and the size of the production line.

Yamato’s global expansion

King said Japan was the birthplace of combination scales, explaining that previous scales, such as linear weighers, would capture product in a single bucket, which produced more variability in the weights and required much more time to weigh.

The speed and precision provided by Dataweigh quickly caught the attention of the food industry, prompting Yamato Scale to expand globally, starting with offices in South Korea and Germany in the 1980s. It now has offices in 14 countries and a workforce of more than 1,100 selling its flagship combination scales in more than 130 countries.

Its largest overseas subsidiary is Yamato Corp., which was established in the U.S. in 1998 with the mission of promoting the use of Yamato Scale products in key markets in the Americas, including confectionery, frozen food, baked goods, snacks and fresh produce. The company has nearly 100 employees in three offices in the Americas.

“We moved into our new facility to support our market growth and expansion in 2021, which was another important milestone,” King said. The U.S. headquarters features a demonstration room that allows customers to see Dataweigh in action.

While most of the machines are manufactured in Japan, Yamato’s U.S. operation plays an important role in global sales, guiding customers through the implementation process, adjustment and maintenance. “We can support all manufacturers regardless of the size of their operation or the level of automation that they require,” King said.

Customization and efficiency

Each Dataweigh is customized to meet the needs of the customer and to fit perfectly in its packaging process.

“No two scales are the same,” King said. The product’s size, volume and other attributes need to be taken into consideration when designing a scale, and this can involve the size, shape and the surface finish of the buckets as well.

“The scale you use to run chips would not be the same scale that you would use to run sugared gummies,” she said. The number of buckets can be the standard 14 or another number. “All of that is determined by the product that is being weighed.”

Yamato has regional service technicians who can rush to a plant when a machine goes down. It also keeps a close eye on its parts inventory to ensure damaged components can be replaced quickly.

This dedication stems from Yamato’s commitment to consistently delivering precision and speed to its customers. For manufacturers of packaged goods, precision is crucial not only for legal and regulatory compliance, but also for maximizing cost reductions and profit.

King explained that typically at the end of the packaging process, before the finished packages are shipped, there is a checkweigher or inspection system that removes underweight products. This means that manufacturers, especially those in the food industry, will not only lose products they cannot repack but also waste packaging material.

She also noted that North America has particularly high standards for sanitation, which Yamato is mindful of, as well as content weight. She added that technologies and machines meeting North American standards can generally satisfy most international requirements as well.

While regulations on overweight packages may be less strict than for underweight packages, excessive overfills can be equally detrimental due to the direct increase in raw material costs.

“If you give away product, you give away profit,” King warned. Minimizing overweights via Dataweigh can help achieve better profit margins and more efficient and sustainable use of resources.

This includes energy. Dataweigh Omega Plus, Yamato’s most innovative and powerful model, has achieved a 60% reduction in power consumption compared with earlier models.

Sustainability remains key

King anticipates that sustainability will remain a key factor in the weighing and packaging industry, just as it is in other sectors. She noted a growing trend in the Americas toward reducing single-use plastics and transitioning to alternative materials, such as paper, cartons, cans or glass. “We can and will continue to fill any type of packaging, regardless of the material,” she affirmed.

She further emphasized that any reductions in waste and energy are a direct result of the high accuracy and efficiency of Yamato’s machines.

“In a sense, we have always been sustainable. Our sales team definitely addresses this to our customers,” because it’s a point that likely resonates with their sustainability goals.

Enhanced automation is another key factor. King foresees heightened demand for automation due to shrinking workforces not only in the U.S. but across the globe. This is another area where Yamato’s machines, developed in a country that has been grappling with the issues of depopulation and a rapidly graying society for some time, hold a distinct advantage and can offer valuable contributions.

King noted that in the U.S. and other countries experiencing high employee turnover, a high level of automation is crucial, along with machine-workforce compatibility. She said that in the past, employees in packaging facilities might have used Yamato’s machines for a decade, turning them into experts. But now that employee retention is dropping to only a few years, she believes that continuous efforts to improve machine “intelligence” and ease of use are essential to mitigate the impact of higher turnover.

She noted that potential enhancements might include self-diagnosis, automated setting adjustments and remote monitoring and access capabilities. These features would be particularly beneficial to manufacturers with multiple plants or production lines, and some of these functions are already built into the Dataweigh Omega Plus.

With constant efforts to update its weighing technology and meet the changing needs of its customers, Yamato Scale and its network of subsidiaries will continue to help its customers increase profits while contributing to the achievement of higher sustainability.

This article is sponsored by Yamato Scale Co. Ltd.