Misumi Group Inc. has supported the manufacturing industry as both a trading company and manufacturer of parts for production equipment and other industrial machinery. Since its founding in 1963, Misumi has focused on creating business models that provide services aimed at improving the efficiency of production sites.

In a recent interview with The Japan Times, President and CEO Ryusei Ono, Chief Information Officer Arata Shimizu, Senior Corporate Officer Mitsunobu Yoshida, and Head of DJ System Promotion Department Tomohiro Yamamoto spoke about Misumi’s value beyond parts manufacturing and sales, and the new services it has created as part of the company’s ongoing digital strategy.

Factory automation has been progressing in Japan’s manufacturing industry, but the design, development, manufacture and maintenance of the parts needed to keep the machinery and equipment running have proven to be time-consuming and laborious.

According to Ono, the reason for this is the long-standing complexity of supply chains and the processes involved in procuring machine parts.

Traditionally, blueprints had to be drafted for each custom-made machine part, which took a significant amount of time. Subsequently, obtaining quotes from manufacturers and distributors, negotiating the terms and placing orders also requires considerable effort and time. Even a delay in a single part can hinder the completion of an entire machine.

Ono said the automation industry, Misumi’s primary customer base, faces the common issue of spending excessive time on procuring machine parts. He further noted that Misumi has long focused on alleviating these burdens, allowing customers to leverage the time saved to generate greater value by concentrating on their core activities: design, manufacturing and maintenance. One early outcome of these efforts was Misumi’s introduction of catalog-based parts sales in 1977.

“We have always been trying to meet the specific needs of each customer. However, responding to each request individually would simply be too time-intensive, so the key challenge lies in standardizing our products and services to handle diverse requests,” Ono said.

Misumi has standardized a wide range of items in various dimensions, tolerances and surface treatments and assigned each one a unique product number. “From then on, customers simply provide the unique product numbers and we deliver the exact products globally,” Shimizu said.

As a result, the range of products has now surpassed 30 million. If dimension variations that can be specified at the micron level are included, the company’s product lineup is astronomical.

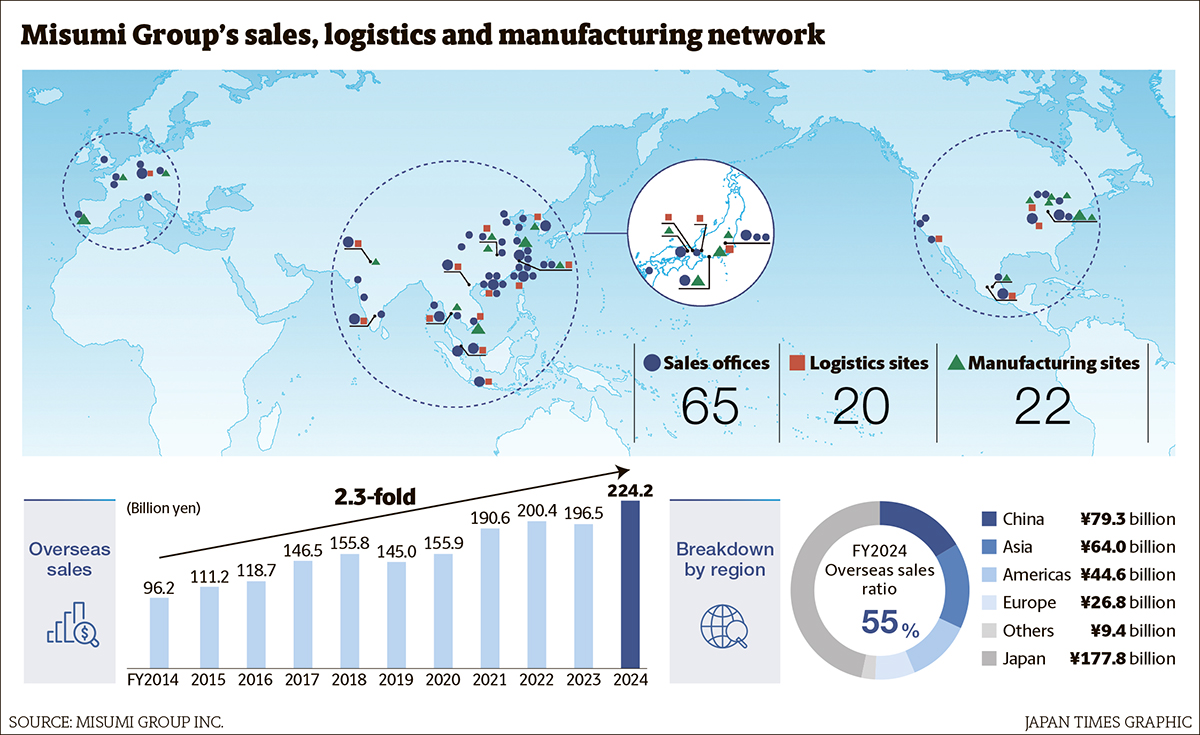

What began as a catalog some 40 years ago has evolved into an e-commerce solution since 2009, now available in 16 countries and regions and 12 languages. “Currently, approximately 55% of sales are overseas,” Ono said.

He emphasized that the company has always concentrated on creating business models that provide time-saving solutions to its customers to minimize time wasted on tasks other than the customers’ core businesses and ensure increased productivity.

In recent years, Misumi has been further promoting its digital strategy, which is supported by the company’s unwavering focus on mass customization through the standardization of products based on individual requirements coming from diversified customer needs.

“All of this starts from the proactive efforts of our employees. As a company, our focus is on creating an environment that facilitates employees’ ability to identify customer needs and market changes, swiftly share gathered information with management and respond accordingly,” Shimizu stated, noting that his hope is to accelerate industrial automation worldwide.

Misumi’s production network spans the northern hemisphere from Vietnam, China, South Korea, Thailand and India to the United States, Canada, Mexico, Portugal and the Czech Republic. Common parts are mass-produced up to a semi-finished state in factories the company runs at lower costs. The required quantities are then completed upon order, mainly in manufacturing sites closest to customers to minimize delivery times and costs. In addition, factories and offices in the network collaborate, enabling items that cannot be produced in one location to be manufactured in another, minimizing opportunity risk.

Digital push paying off

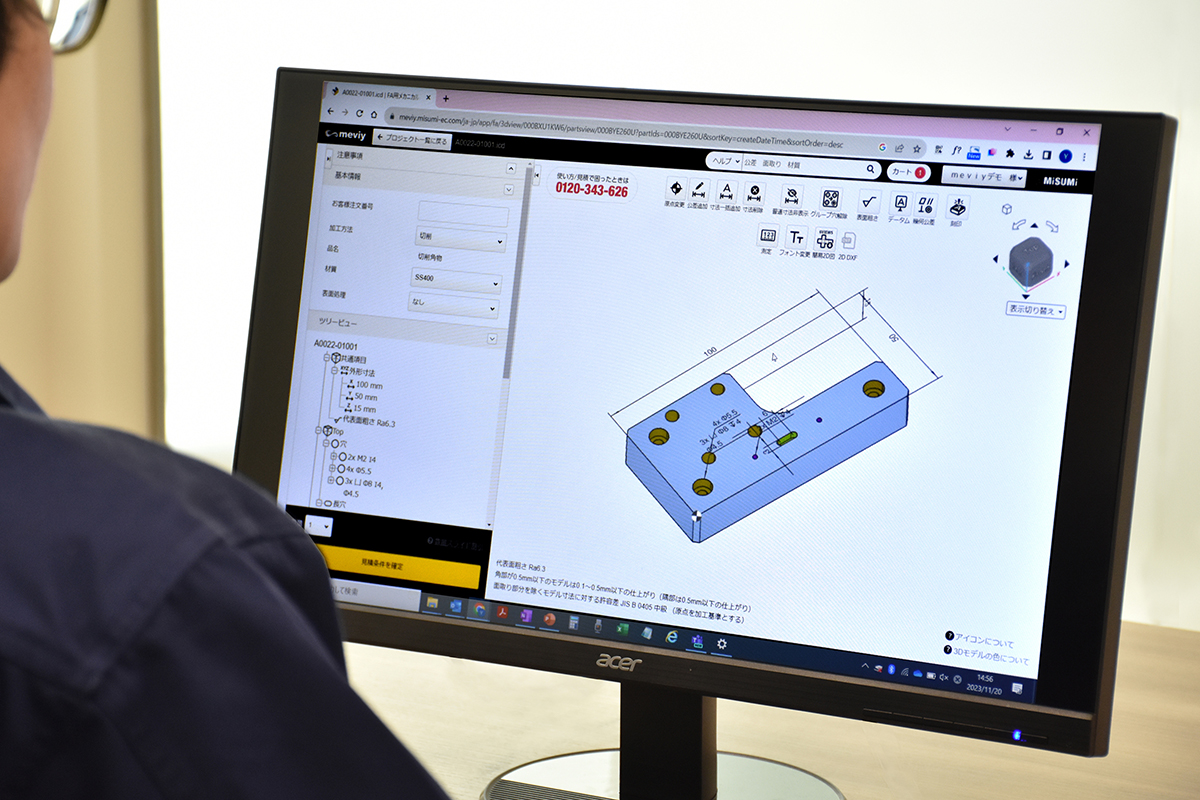

In addition to the advantages of its global network, Misumi’s recent digital strategy provides an option for make-to-order products through the meviy service, which was fully launched in 2019. This allows customers to freely design machine parts in various sizes, materials and shapes.

Even for parts not listed in Misumi’s catalog, meviy allows procurement by uploading a 3D computer-assisted design file created by the customer. Once uploaded, meviy’s artificial intelligence program can instantly and automatically provide feedback on manufacturing feasibility, price and delivery dates. Upon order confirmation, the data is sent to the company’s factory, where the manufacturing starts automatically. The service supports sheet metal, welding, cutting and resin processing, and accepts orders for a single unit or large quantities.

According to Yoshida, who leads Misumi’s ID Business Company, for most companies the procurement process for machine parts typically requires tremendous time and effort, starting with 30 minutes per drawing and then faxing them to multiple companies for quotes.

“A large-scale survey we conducted a few years ago revealed that 98% of manufacturers still used fax machines for quotes,” he said. This process is followed by a week of waiting for quotes to be considered, and two to three weeks for production. This time-consuming and labor-intensive process can be repeated for 1,000 or 2,000 different parts when complex machinery is involved.

Catalog sales were an initial attempt to streamline this, but Yoshida said this only satisfied about half of its customers’ needs.

“Customers are facing a shortage of time due to a shortage of labor. Despite this, significant time is still spent on procurement. Ideally, people should dedicate more time for creative work, such as developing better products and designing more productive equipment,” Yoshida said.

Meviy’s development was partly driven by the decline of Japan’s small to midsize factories, which constitute the majority of the supply chain. According to Misumi, many of these factories have been facing pressing issues such as an aging workforce, a lack of successors and delays in adopting IT tools, and if the situation is left unaddressed, it will affect the productivity and sustainability of the manufacturing industry as a whole.

To solve this urgent issue, Misumi is continuously promoting strategies to advance the ongoing shift of its digital model, starting with meviy.

Models evolve, save time

For global expansion, customized solutions for addressing global variations in measurements and standards are essential. To prioritize the rapid development of customized features, Misumi set up its first tech company, DT Dynamics Corp., in 2022.

Meviy offers flexible delivery and pricing options. Upon uploading the design data, customers are presented with multiple options. For example, when there is ample lead time, selecting a longer delivery time allows for overseas manufacturing, thus providing a cost-saving mechanism.

“Customers sometimes need parts urgently due to equipment failures, while at other times, they conduct planned, cost-sensitive procurement. So, we provide a wide range of options,” Yoshida said, noting that meviy’s time-saving mission resonated well in Europe and North America, where labor costs are higher, as well as in China, where labor costs are rising rapidly.

Another key feature of meviy is its ability to analyze design data, explain why certain designs are not viable and suggest how the designs should be changed. Meviy analyzes design errors that customers fail to notice while designing with 3D CAD software. It even suggests corrections through a trial and error process, which also contributes to the nurturing of future engineers.

In 2024, a new marketplace-type service expansion was launched called meviy Marketplace. This business model enables direct order placements between customers and suppliers.

Furthermore, the acquisition of Oakland, California-based Fictiv Inc., an online procurement platform company for custom mechanical components, was announced in April. Founded in 2013, Fictiv has a global manufacturing network that includes China, India and Mexico and has recently shown rapid growth. It also has a high business affinity with meviy, contributing to customer expansion worldwide.

In Japan, meviy was awarded the 2023 Prime Minister’s Prize under the Monodzukuri Nippon Grand Award program, which recognizes excellence in manufacturing.

“Misumi considers itself to be the infrastructure of manufacturing. Infrastructure is something that is so commonplace that it is often taken for granted, but even a single missing screw can bring an entire factory line to a halt. It is our responsibility to continue creating business models that contribute to the sustainability of the manufacturing industry as a whole,” Yoshida said.

Inventory simplified

Another new core service in Misumi’s digital strategy is Digital Just-In-Time, which tracks the parts inventories of affiliated suppliers around the world to ensure full orders, large or small, can be rapidly completed.

Whereas meviy connects the platform directly to the factory, D-JIT networks suppliers to bring them closer to customers.

Since its launch in 2024, about 70,000 companies in Japan and abroad have already utilized D-JIT.

Misumi handles a vast range of products known as “indirect materials.” These include tools, supplies, maintenance parts such as screws and washers, and on-site supplies and consumables.

According to Yamamoto, who leads the D-JIT business, customers are spending a significant amount of time and effort on procurement activities especially for large quantities of manufacturing components, which often involves finding multiple suppliers and placing multiple orders to achieve the required quantities. Improving the efficiency of these activities is a critical challenge. This is where D-JIT contributes to customers, offering a fundamental solution to the sourcing process.

Efficient logistics are critical

The development of D-JIT is deeply intertwined with Misumi’s new core system, Newton. The algorithm that combines inventory status and production capacity information from over 500 suppliers worldwide in real time and automatically displays prices and delivery dates would not have been possible without this core system. By connecting inventory information from many suppliers, Misumi’s virtual inventory has increased dramatically.

Misumi plans to further roll out D-JIT overseas in addition to South Korea, Thailand, Taiwan and some European countries where it is already in operation, with an aim to expand and strengthen partnerships with local suppliers.

Efficient logistics are also crucial for quick delivery. Misumi has enhanced efficiency by operating its own warehouses and distribution centers. Yamamoto stated that their proactive investment in logistics in high-volume areas, while considering local conditions, remains a consistent approach to global expansion.

“In the procurement of machine parts, mechanisms to eliminate inefficiencies are evolving rapidly. However, Misumi is focusing on inefficiencies where such progress is delayed and promoting operational efficiency through digital transformation. D-JIT also aims to contribute to this effort,” Yamamoto said.

Misumi Floow: Vending machines that save time on ‘indirect materials’

Just launched in April, Misumi Floow is a new service designed to bring about more efficient procurement of “indirect materials” frequently used at manufacturing sites.

Mass production factories face challenges with the procurement of diverse, low-volume, and irregular indirect materials like tools and consumables. This requires repetitive manual tasks such as sourcing, receiving, inspecting and stocktaking, hindering efficiency.

Under Misumi Floow, vending machines are installed on-site, allowing workers to retrieve the most frequently used items directly from Misumi, which restocks the machines, eliminating the need for inventory management.

This service was first introduced in China, where over 1,700 vending machines have already been deployed at about 420 factories. In Japan, the service was tested in about 50 factories ahead of its official launch. According to Misumi, the use of Misumi Floow contributes to a 70% reduction in time spent on procurement tasks.

Data on the items used is recorded and visualized in the system, showing who used what and when, which can also help prevent fraud.

This article is sponsored by Misumi Group Inc. Please visit https://www.misumi.co.jp/english/