In current times where issues concerning climate change and global warming persist and a further reduction in carbon emissions is needed to ensure the survival of future generations, Eneco Hybrid HHO Gas developed by Eneco Holdings Inc. may be the key to realizing a zero carbon emission society.

The new technology is capable of generating massive volumes of oxyhydrogen gas using only a very small amount of electricity. The technology is also expected to cut the price of HHO gas by more than two-thirds of the current average price. And, above all, it can generate HHO gas without emitting any carbon dioxide.

The company’s fundamental rethink about energy and development of the ingenious Eneco Hybrid HHO gas product is a game-changer.

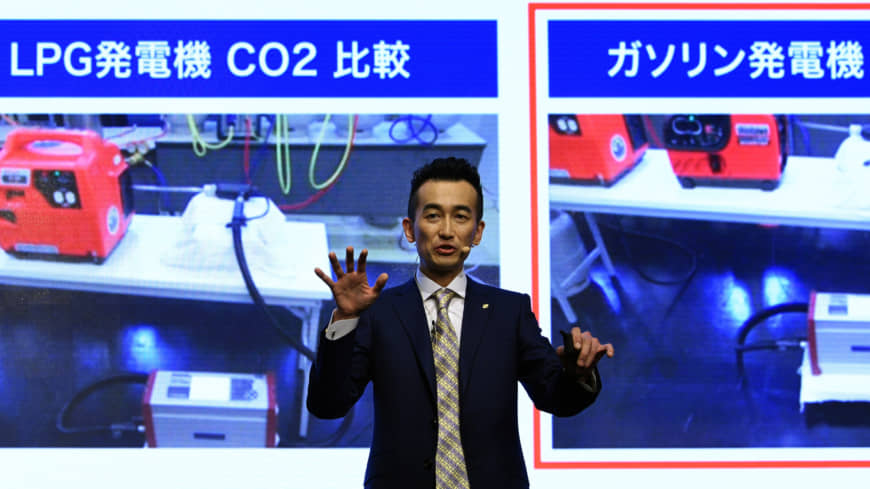

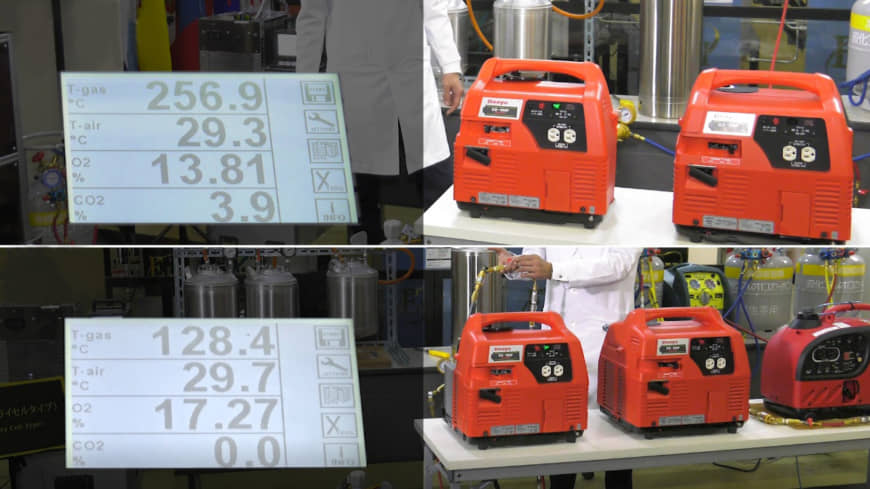

“Our mission is to help realize and contribute to the creation of a sustainable society for generations to come,” Eneco President and CEO Yasuhiro Yamamoto said at a press conference held in Tokyo in June to announce details of the innovative technology. The water and fuel technology specialists are committed to improving the global environment for future generations, paving the way to help realize a world without carbon dioxide emissions.

“We are committed to providing fuels where they are needed without negatively impacting the environment,” Yamamoto said, stressing that fossil fuel supplies are likely to run out within several decades and that dependence on such fuels has produced massive amounts of carbon dioxide.

An innovative alternative

The procurement of raw materials to produce hydrogen has until now imposed a significant environmental burden, because hydrogen must be either extracted from something or generated through chemical reactions. “The massive amount of fossil fuels used to create and deliver hydrogen generate carbon dioxide at the same time,” Yamamoto said of traditional methods to generate hydrogen fuel.

Hydrogen fuel has attracted global attention as an environmentally friendly fuel compared to its fossil fuel counterparts. Developing a manufacturing method that can provide a stable supply of hydrogen more safely, more reasonably and with less environmental impact has been key.

“Some companies extract hydrogen from fossil fuels, natural gas and liquefied petroleum gas, while other companies produce hydrogen from a gas, which is a byproduct of steel manufacturing or from biomass (waste combustion). It can also be generated from renewable energy sources,” Yamamoto said. “But we thought it best in terms of cost and environmental impact to use an evolved application of the principle of water electrolysis.”

Yamamoto explained conventional approaches to extracting hydrogen from water. One is a water electrolysis method that does not require much electricity, but cannot generate mass volumes of hydrogen. The other is a dry-cell method that is costly due to the large amount of electricity required. Eneco has been exploring these methods to generate mass volumes of hydrogen using minimum electricity.

According to Yamamoto, whereas conventional electrolysis uses electricity to decompose water into hydrogen and oxygen, Eneco’s technology uses a proprietary catalyst to generate HHO gas, a mixture of hydrogen and oxygen. The innovative gas contracts as it burns while taking in its own oxygen — imploding instead of exploding.

A video played at the press conference showed the chemical reaction that occurred — HHO starts to rise in less than a minute — when water was poured into a tank containing the catalyst.

“I cannot disclose what our catalyst is made up of because it’s a patent-protected technology. But I can tell you that it is made from a waste that is safe and easy to obtain,” Yamamoto said.

The new technology only requires a very small amount of electricity to run a monitor on the firm’s Eneco Plasma R Hydrogen Gas device, but Yamamoto said any such electricity could also be self-generated. “You just have to start the HHO gas generation process and use any initially released gas to power a generator. Then use that electricity to turn the monitor on,” he said.

Hydrogen-producing machines

An original version of the Eneco Plasma R Hydrogen Gas apparatus was released in 2016. However, recent improvements have seen hydrogen-ionized water used instead of tap water so that the product is more efficient. “This improved HHO gas device can replace all energy sources including fossil fuels, natural gas and propane gas,” said Yamamoto.

“We are also developing an even more compact fuel cell to replace generators. The entire system therefore becomes electricity and carbon dioxide emission free,” said Yamamoto. “Our self-sufficient HHO gas generator will not only be environmentally sustainable, but also highly effective in remote areas where electricity is difficult to access.”

“Hydrogen-ionized water can be made by placing ore in the water and increasing water pressure and temperature. This water can have a maximum of 360 times more hydrogen than tap water,” said Yamamoto. He also explained that while conventional dry-cell methods to extract hydrogen from water typically only attain a fixed rate of 67 percent hydrogen and 33 percent oxygen, the HHO produced by Eneco initially boasted 82 percent hydrogen. “This newly developed Eneco Hybrid HHO Gas allows proportional adjustments of hydrogen, between 50 to 100 percent,” said Yamamoto.

Shinichi Sugiura, professor of the Department of Clinical Pharmacy at Doshisha Women’s College of Liberal Arts, conducted an experiment to measure the concentration of hydrogen gas provided by Eneco and other samples. Eneco submitted the highest-concentration hydrogen gas generated by its device. Sugiura was surprised to find that the concentration of Eneco’s gas was even higher than the Japanese Industrial Standards’ level three hydrogen, which is basically regarded as an industry standard substance.

The new HHO gas technology has also achieved high-cost performance. “Our technology is expected to bring down the price of HHO gas to less than one-third of the current average price,” said Yamamoto. “It is no wonder that current prices are high — a dedicated plant needs to be established to extract hydrogen out of fossil fuels, tankers and trucks are required for hydrogen transportation by sea and road, and hydrogen stations need to be built to store the fuel,” Yamamoto said.

Only 108 of these facilities existed across Japan as of June this year according to the Next Generation Vehicle Promotion Center. Conversely, according to the Ministry of Economy, Trade and Industry, the number of petrol stations in Japan was 30,747 as of March 2018 and the number of public charging facilities of electric vehicles and plug-in hybrid vehicles was 27,835 in 2016.

“Our HHO gas device is extremely cost effective. It does not require any infrastructure, which minimizes the scale of capital investment. You can make as much fuel as you need when you need it, with only water and the catalyst, without having to worry about large storage,” said Yamamoto.

The device can produce 2.4 tons of HHO gas per day. Eneco plans to commercialize the technology for residences, vehicles, ships, aircraft, factories and plants, thermal power generators and rockets.

“If our device is installed at a house, the whole house can run only on HHO gas instead of electricity or propane gas for about ¥2,000 per month, using only eight liters of water,” Yamamoto said. Eneco is planning an event in September to showcase such examples of commercial use of its technology.

“While (our) Eneco Plasma Fusion blends fossil fuel and water, HHO is an even better option in that it achieves zero carbon dioxide emissions,” said press conference attendee Colin Moran, CEO of Eneco Energy Ltd. in Singapore. Moran noted that one of HHO’s obvious benefits was that fuel could be produced without having to import or blend any components. “The cost of fuel is disproportionately high in countries like Laos compared to the GDP per capita. Eneco’s HHO technology will greatly save on import costs. In addition, bringing transportation costs down will be a boost for the economy,” he said.

Chong Ning, managing director of the Hong Kong-based China Fund Capital Management Ltd., working across Hong Kong, Macau and mainland China, said the Chinese government welcomed the introduction of hydrogen energy to the mainland market. “The government is encouraging us to apply for a license to sell hydrogen energy to China,” he said.

Yamamoto stressed that when hydrogen is generated from water the way that Eneco has made possible, it is the only source of energy that realizes zero carbon dioxide emissions.

“We plan to form partnerships with companies across the world and venture deeper into the markets of more than 200 countries in Asia, Europe, North America, South America and Africa,” said Yamamoto.

Reducing fossil fuel reliance

Eneco has already garnered a reputation for its internationally commercialized, state-of-the-art emulsion fuel; these fuels are composed of water and combustible liquids such as oils. The purpose of emulsion fuels is to reduce total reliance on fossil fuels by replacing some of these fuels with water.

According to Eneco, conventional emulsion fuel technologies display weaknesses such as a reduced potency, a separation of water and oils over time, and the need to convert facilities or engines to accommodate the viscosity of emulsion fuels.

“In 2015, we succeeded in developing an emulsion fuel that achieves a complete fusion of 50 percent oil (heavy oil, light oil, kerosene or biodiesel) and 50 percent water,” said Yamamoto. Eneco Plasma Fusion equipment, a device to create Eneco’s unique emulsion fuel, overcame the shortcomings of conventional emulsion fuels. “There is no need to make changes to facilities or engines designed for conventional fossil fuels. Simply replace the fuels with our emulsion fuel, and you will achieve the same result. The water and oil do not separate over time, thus minimizing any chance of damage to the vessels in which the fuel is used,” said Yamamoto. “Moreover, our fuel can cut carbon dioxide emissions roughly by half.”

Eneco has experimented across various international markets using local water and local oil since the plasma fusion technology was launched. The product has passed standards in several countries including Indonesia, Bangladesh and the Philippines, where the invention is already in operation.

Companies in Australia, Singapore, Hong Kong, Laos and Myanmar will next implement the device. Colin Moran said that Singapore is working to introduce Eneco Plasma Fusion not only in Singapore, but also in Laos, Myanmar, Vietnam, Malaysia, East Timor and Cambodia.

“The Singapore branch is Eneco Holdings’ representative in Southeast Asia, and Laos is the first country we have helped. We also have a large logistics company with over 150 trucks in Singapore; this has enabled us to test the emulsion fuel in a real-life situation,” said Moran. Singapore is preparing to showcase Eneco’s technology and provide working case studies for the other regions.

A ceremony to commemorate the introduction of Eneco Plasma Fusion in Laos took place at the Tokyo press conference. Somvang Khurulat, CEO of DNM Corp. Public Company in Laos, said the device will help reduce the costs associated with importing diesel oil while making the environment greener.

Henry Heng, managing director of Eneco Refresh Ltd. in Australia, said the country’s mining industry was an ideal market because many mines are located in remote areas off the grid and use diesel to generate electricity. “Our emulsion fuel technology would also benefit Australia’s transportation industry as the land is so vast,” Heng said.

Chong Ning commented: “We are already in agreement with the Jiangxi government in the northern part of China to import Eneco Plasma Fusion technology in three months time. The emulsion fuel will be used mainly for transportation.”

“In Japan, we received approval to manufacture Eneco Plasma Fusion fuel as it was confirmed to have met the standards for light oil in terms of taxes,” said Yamamoto. “Eneco Plasma Fusion fuel became the first emulsion fuel to be approved for production in Japan.” Even with the same tax rate as light oil applied, the fuel still costs a third lower than light oil according to Yamamoto. “Tests in which buses use our fuel have demonstrated that our emulsion fuel can reduce carbon monoxide and carbon dioxide emissions by about 50 percent.”