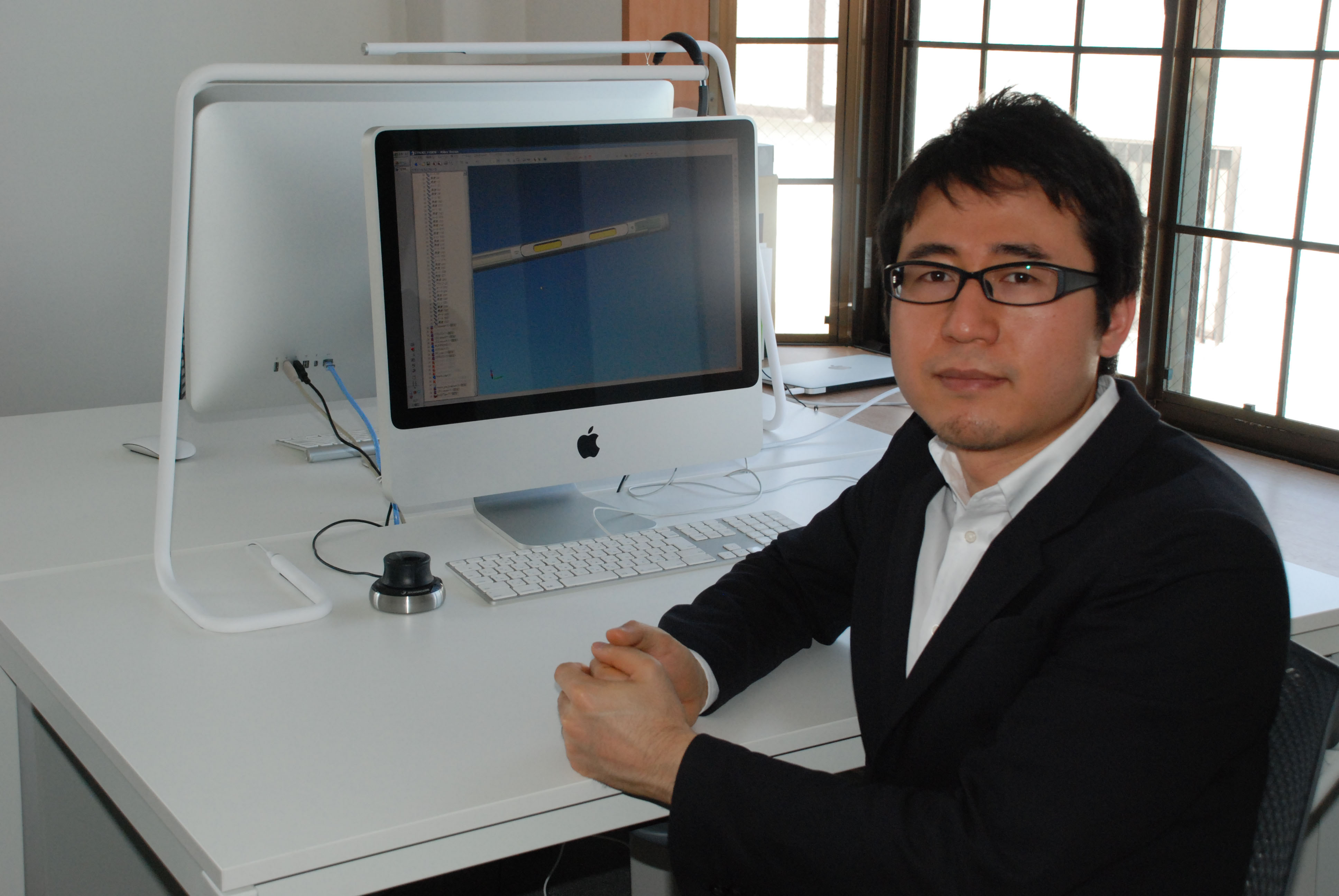

Surrounded by fields and houses on the outskirts of Odawara, Kanagawa Prefecture, few people would recognize this office as the headquarters of an electronics company. But this is where Keita Yagi runs Bsize Inc., making, designing and selling products all on his own.

Since founding the startup in September 2011 in Odawara, a bucolic city over 70 km southwest of Tokyo crowded with other venture firms, Yagi, 30, has developed and sold 1,000 of his Stroke desktop lamps online, taking advantage of common tools now available in today's digital age.

The design of the LED lamp, which emits light from the end of a tube, has won awards in Japan and Germany for its minimalist design.